Filament Winding

Process Overview: Filament Winding

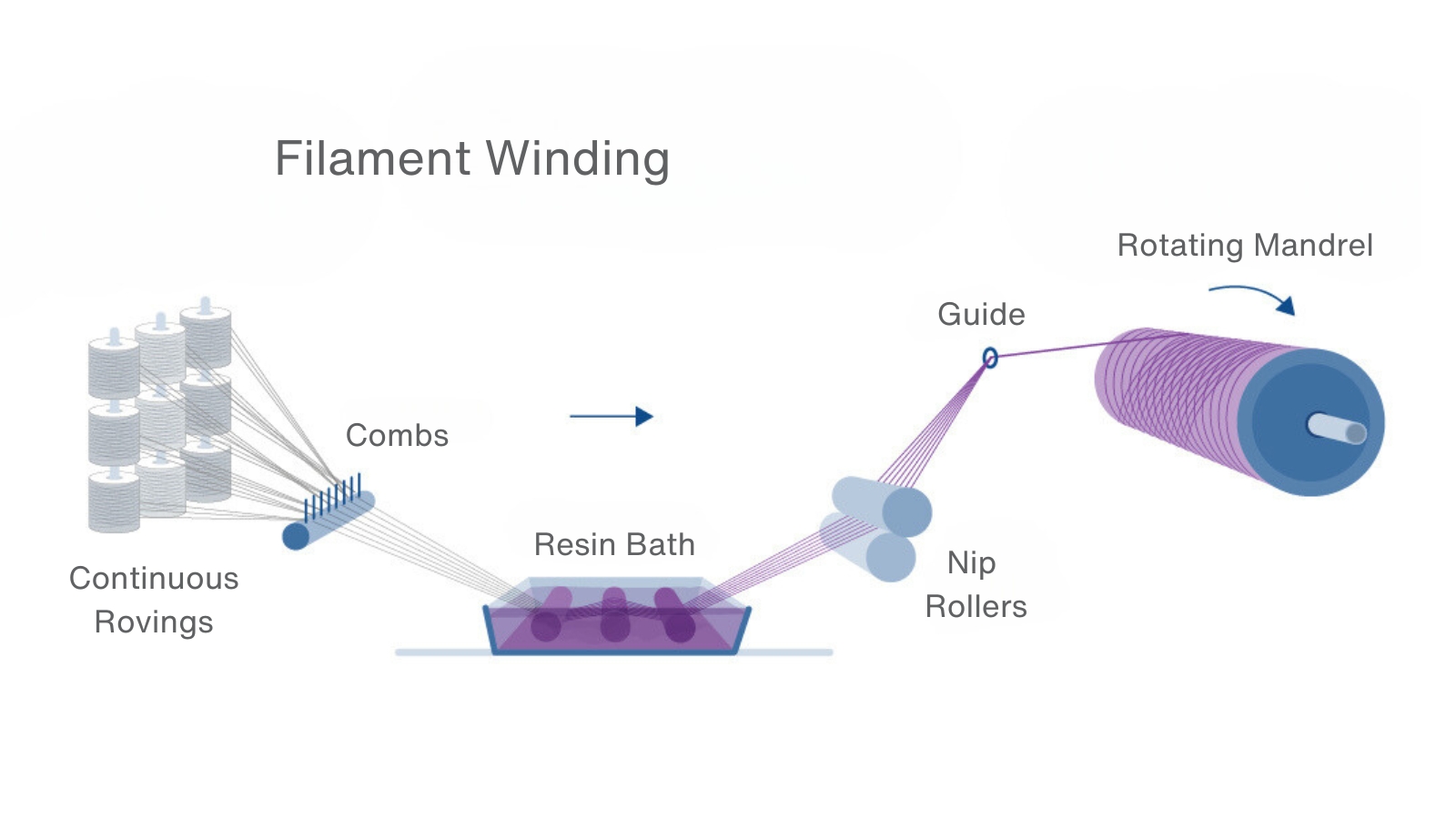

Filament winding, widely used in the manufacture of tanks, pipes, and other cylindrical parts, is an open molding process where resin saturated continuous fibers are wrapped around a rotating mandrel to create an axially symmetric structure with a high degree of structural integrity.

The filament winding process can incorporate a variety of resin systems and fiber types depending on the end-use part application. In this process, continuous rovings, yarns or tow are first pulled through a catalyzed resin bath. Excess resin is removed from the fibers which are then guided onto a rotating mandrel or mold via a carriage arm that moves along the length of the mandrel ensuring the fibers are evenly applied. The movement of the carriage arm and the rotation speed of the mandrel are synchronized through automated controls to achieve precise fiber placement and structural integrity of the laminate. Once the desired laminate thickness is achieved, the part is allowed to cure either at room temperature or with the addition of heat and is then removed from the mandrel for additional processing.

Example Filament Winding Applications

Filament Winding

Chemical storage tanks

Pressure vessels

Cement mixers

Tubing and pipes

Natural gas cylinders

Sailboat masts

Aerospace components

Technical and HSE Support for Filament Winding

Composites One offers personalized technical support for customers manufacturing with the process of filament winding, as well as the most up-to-date information on regulatory and compliance requirements.