August 9, 2021 ~

Efficiencies of Kitting and Plying for Processing Advanced Composite Materials

When

Thu, Aug 19, 2021

1:00 PM Central Time (US & Canada) (GMT -5:00)

About

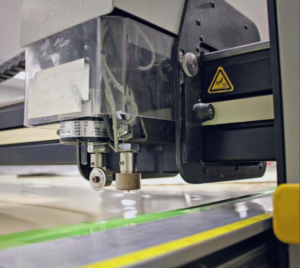

The composite part manufacturing process requires valuable time requiring technicians to tailor materials, including prepeg, advanced reinforcements, vacuum bagging, and processing materials, to fit the mold. In the moment tailoring can lead to inconsistent part quality and performance.

Cutting technicians from companies like Aerovac Composites One and Mission Critical Composites are experts at nesting ply shapes to maximize yields and minimize waste of high-value materials. This combined with temperature, humidity and particulate-controlled environments protect materials during processing. When combined with Composites One material and supply chain management solutions, manufacturers can benefit from a streamlined supply chain, simplified cost modeling and reduced overhead costs.

Presented by:

James Knox

James Knox

Global Technical Service Manager, Aerovac

James Knox is the Global Technical Service Manager for Aerovac. He has 25 years of experience in various manufacturing and commercial roles, the majority of which is within the composites industry. His area of expertise is in Process Materials for the production of composites, and his background includes extensive experience in the carbon fiber industry. His current role is to manage a team that provides Technical Service to Aerovac’s customers globally. He holds a Bachelor of Science degree in Chemical Engineering from Clemson University, and a MBA from the University of South Carolina.

Lisa Ewald

Lisa Ewald

Director of Aerospace, Composites One

Lisa Ewald is the Director of Aerospace for Composites One. She has 26 years of experience in sales and marketing of composites materials, both as a manufacturer and distributor. Her background is in resin and gel coat chemistry, but she has spent her career developing her knowledge and understanding of the complete breadth of composite raw materials and supply chain. Her most recent work has been in helping to create a robust product portfolio in Aerospace that includes Time and Temperature Sensitive Materials from the top Aerospace Material Manufacturers in the world.

Robert Hartman

Robert Hartman

President, Mission Critical Composites

Robert Hartman’s background spans over 30 years in executive management with extensive experience in business development, building company infrastructure including establishing strategies in national and international markets. His formal business experience includes founder/co-founder of three high-tech manufacturing companies and in-depth expertise in composites for the aerospace, defense and commercial space manufacturing industry for the past 12 years.

Mr. Hartman’s aerospace and defense background began with working experience on the Nike Hercules Missile program in the late 1970s. He subsequently worked in the Silicon Valley technology industry for 20 years serving as founder/co-founder of several software and hardware manufacturing companies including a role serving abroad for computer hardware manufacturer Able Computer as director, European markets.

In 2008 Mr. Hartman formerly became vice president, Business Development for AAE Aerospace, America’s leading composite rocket propulsion company responsible for creating the THAAD missile and Virgin Galactic’s Spaceship One/Two propulsion systems including the first rocket nozzles for Elon Musk’s SpaceX rocket program. His work at AAE also focused on expanding additional markets in the composite rocket propulsion manufacturing sector, identifying and analyzing business opportunities and expanding market share and driving growth. During his tenure at AAE Aerospace, Mr. Hartman formed a separate division, Mission Critical Composites (MCC) in 2010 and spun the company out in 2012 as a separate, veteran-owned LLC company focusing on prepreg plying/kitting including manufacturing composite parts and structures for the defense and commercial space industry. As president of Mission Critical Composites, Mr. Hartman has been successful in establishing MCC as a high-growth composites company providing production-ready plied composite type materials to the composite manufacturing industry including manufacturing critical flight hardware for the warfighter/defense industry and expanding commercial space travel markets.

Mr. Hartman holds a Bachelor of Science degree in finance with honors from University of California, Northridge.